Aviation

Backed by our EASA approvals for Design, Production and Part 145, we at TEG take full responsibility and accountability for all your aircraft requirements.

We supply a Turnkey Solution.

The combination of these three certifications offers customers a faster and more streamlined service. You, the customer, know TEG is taking full responsibility for the project because you are only dealing with one organisation.

TEG has worked on AOG and urgent parts for airlines and MRO’s, often using OEM engineering data such as Boeing SMAL or Airbus Authorisation Letter.

A comprehensive Aircraft Transition Package allows aircraft lessors to pick and choose from the menu of options.

Key Capabilities

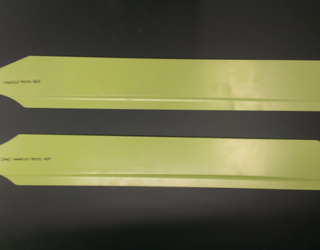

The range of engineering capabilities is one of the key strengths of the company. For you, the customer, it means there is a very strong likelihood TEG can fully manufacture the part(s) you require using in-house capabilities. This leads to faster response times, which can be particularly important for an urgent or AOG part. The key capabilities include:

- Short & Long Bed Machining

- Turning

- Electro Discharge Machining (EDM)

- Grinding

- Bending, Forming & Rolling

- Assembly

- Welding

- Anodizing

- 3D Additive Manufacturing

Design Competencies

TEG has a very strong design engineering department. NX Unigraphics is a state-of-the-art software computer aided design (CAD) package. TEG has a total of 22 seats of NX Unigraphics. This CAD package is particularly suited for handling large amounts of data, which is very important for ensuring the accuracy of aircraft parts, some of which have multiple contours and merging surfaces.

Project and Programme Management

Whole Value Chain control of Design, Engineering, Production and Quality Assurance ensures projects are delivered rapidly and are effectively managed for TEG customers.

Detail Overview – Scope of Approvals

EASA Part 21/(G) Production Organisation

Structural metallic. non-metallic aircraft parts and assemblies

EASA Part 145 Approval – Repair

Class:

Components other than complete Engines or APU’s

Rating:

C6 Equipment

EASA Part 21 (J) Design Organisation

Fuselage

Control Surfaces

Empennage – Tail

Wings

Landing Gear

Cabin Interiors

Cargo Compartments

EASA Part 21/(G) Production Organisation

Structural metallic. non-metallic aircraft parts and assemblies

EASA Part 145 Approval – Repair

Class:

Components other than complete Engines or APU’s

Rating:

C6 Equipment

EASA Part 21 (J) Design Organisation

Fuselage

Control Surfaces

Empennage – Tail

Wings

Landing Gear

Cabin Interiors

Cargo Compartments

Our Aviation Services:

At TEG we pride ourselves on our agile approach,

ensuring rapid responses and a quick turnaround on even your most complex projects. Our transparent pricing model and straightforward ordering process ensures there are no surprises, letting you focus on keeping your aircraft in the air.

More About UsReady to discuss your project requirements?

Get in touch now