Testing and Validation

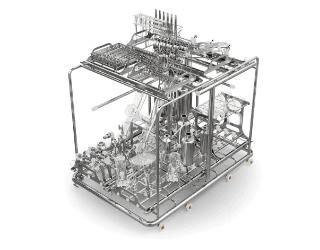

Rigorous factory acceptance testing is carried out on every order to ensure we can stand behind our validation on every part that leaves the TEG premises.

TEG Have a new state of the art testing facility in Ireland for simulating your parts washing equipment for coverage testing.

Using Riboflavin and UV light we have developed ways to test very accurately the performance of your racks before shipping them, resulting in a ‘plug and play’ set of equipment when they arrive onsite.

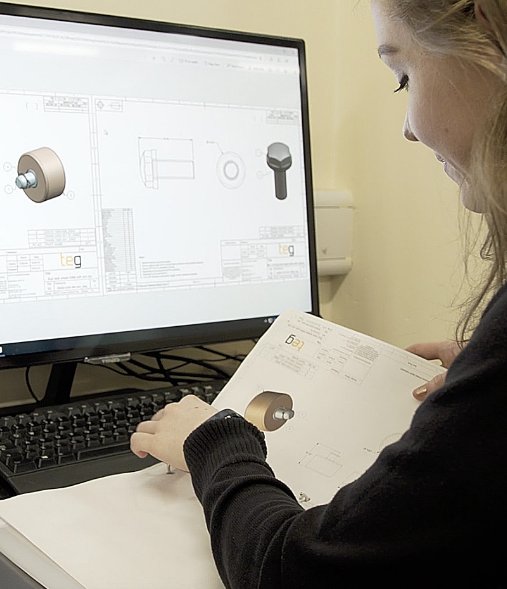

Our Validation documentation is best in class with our dedicated team of engineers generating the detailed drawings and Engineering Turnover Packages (ETOP) for each project. Depending on the level of support documentation required, we can offer some or all of the following for each project:

| Section | Description |

|---|---|

| 1 | System Description |

| 2 | Equipment Index |

| 3 | Equipment Requisitions |

| 4 | Equipment Specifications |

| 5 | Purchase Orders |

| 6 | General Arrangement |

| 7 | Component Cut Sheet |

| 8 | Bill of Materials |

| 9.1 | Material Certifications / Mill Certs |

| 9.2 | Detail Sheets |

| 10 | Test Instrument Calibration Certs |

| 11 | Change Control Procedures |

| 12 | Test Results and Certs |

| 13 | Welding Procedure Certification |

| 14 | Welder Qualification Qualification |

| 15 | Weld Inspection Records |

| 16 | Weld Maps |

| 17 | Passivations Records, Procedure, Etc. |

| 18 | Recommended Spare parts list |

| 19 | Isometric Drawing List |

| 20 | Name Plate Data |

Additional Bio-Pharmaceutical services

For more information download our bio pharmaceutical brochure

Download BrochureReady to discuss your project requirements?

Get in touch now