Testing

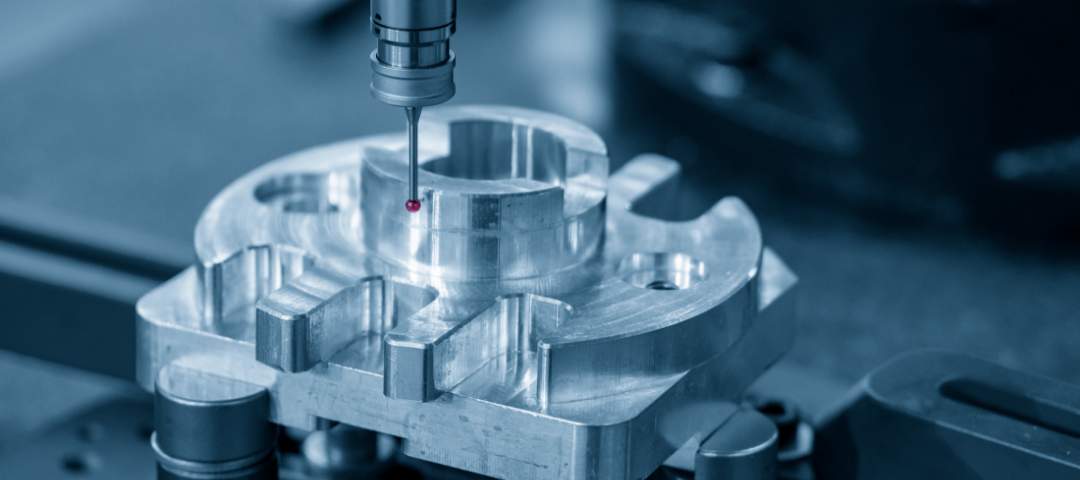

Extensive factory and site acceptance testing is performed on every project we undertake ensuring the highest quality output every time

Quality is the cornerstone of TEG’s offering and we pride ourselves on offering blister tooling of the highest standard.

Even at the early stages of the process all new blister designs are reviewed by our engineering team to ensure they meet all necessary requirements.

Every tooling component is checked to ensure it meets our rigours standards and matches up to the exact design requirements to it meets our highest standards

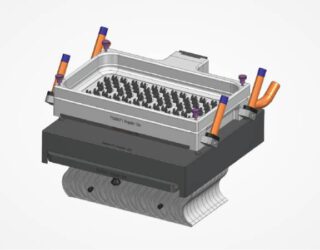

Every feeder that is manufactured in TEG and is rigorously tested before shipping to our customers. Each feeder is tested and optimised to ensure it reaches its peak performance for a given format.

Each feeder supplied by TEG is accompanied by a full validation package.

TEG can also assist customers with site acceptance testing (SAT), to ensure you get your new tooling into production as soon as possible. Our dedicated team of technicians can help get

Other Blister Packaging Services

For more information download our blister packaging brochure

Download BrochureReady to discuss your project requirements?

Get in touch now