NG Feeder on CAM NMX

The Objective

A large pharmaceutical manufacturer in the Middle East was using a CAM NMX machine to package a two products that were high volume products.

The first product was being packaged on a thermoform blister using a vertical feeder. Tablets were repeatedly locking on the tracks due to large tablet tolerances and the maximum output was 26 index per minute or 156 blisters per minute.

The second product was being packaged on a Coldform blister using a drum feeder. Due to shape of the product feeding was limited to 24 index per minute and dust from the product was causing issues.

They customer asked us to look at each format and see how we could reduce the feeding issued while also increasing output.

An extra requirement was that in the future each format might move to a CAM M92 machine so any feeder that we supplied had to work on both machines.

The Approach

TEG first looked at the issues that the customer was facing with their current feeders in order to get a better understanding of what we could do to resolve the issue.

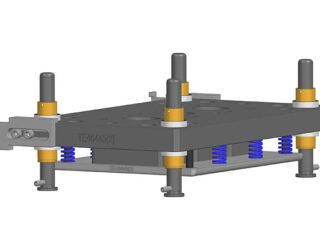

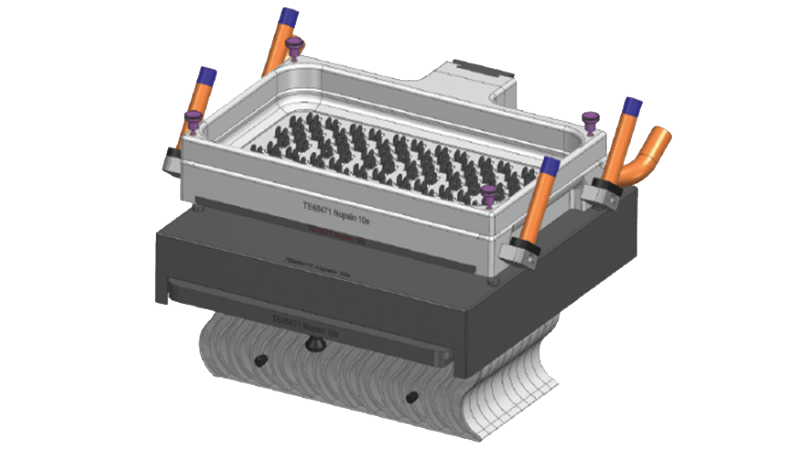

After looking into these and assessing each product we determined that an NG feeder that fed 2 index at a time would be the best solution.

We determined that due to the size of the first product, in order to feed at the required speed a feeder that only fed 1 index at a time would not give us the output needed as collection of tablet was slow. A feeder that fed 2 index at a time would reach the required output.

With the built in NG dust extraction, all dust from the second product would be removed meaning easer feeding with less blockages. A set of Double NG change parts were also needed to reach maximum speed.

The Results

TEG completed all FAT testing of both feeders at TEG with both reached the required feeding speed.

TEG technicians installed the new NG feeding system and provided on site training to the customers operators on the operation of the feeder.

Both feeders were installed successfully and helped increase production output to 40 index per minute, a 60 increase over the previous feeders. Duct collection was also successfully used which removed any downtime previously being experienced.