AOG Support with EASA Form 1 Certified Parts

The Objective

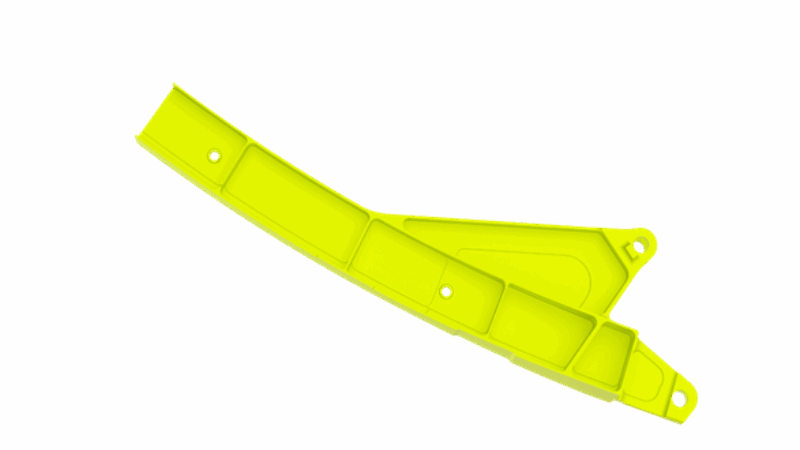

During scheduled maintenance, an MRO discovered cracking on a critical aft cargo door fitting. The part required urgent replacement, but OEM lead times were too long to keep the aircraft on schedule – creating a risk of an extended AOG (Aircraft on Ground) event. With OEM approval for local manufacture, the MRO turned to TEG to produce a fully compliant EASA Form 1–certified replacement within a very tight timeframe.

The Approach

TEG mobilised immediately. Using OEM drawings, our engineering team developed a precise 3D model of the fitting – measuring roughly 920 x 320 x 90 mm – and machined the component from a solid aluminium billet using our multi-axis CNC capability.

The part then moved through TEG’s aerospace finishing process, including:

-

Shot peening for fatigue resistance

-

Surface treatments and coatings to OEM spec

-

Full Quality Control inspection prior to release

All manufacturing was completed in-house under TEG’s aerospace quality system, enabling us to issue a compliant EASA Form 1 on completion.

The Results

TEG delivered a certified, high-precision replacement part within the MRO’s maintenance window – preventing an AOG event and avoiding unnecessary cost and disruption.

The MRO and operator valued our:

-

Fast and reliable turnaround

-

Full regulatory compliance

-

Precision engineering and finishing

The aircraft returned to service on schedule, demonstrating TEG’s capability as a trusted AOG and rapid-response manufacturing partner for the global aviation sector.